LG10 High Speed Continuous Cold Pilger Mill for Stainless Steel Seamless Tube Making

Add to Cart

LG10H Cold Pilger Mill Details:

| No. | Name | LG10H | |

| 1 | Shell OD(mm) | 10~25 | mm |

| 2 | Shell WT(mm) | 0.9--4 | mm |

| 3 | Shell Length(mm) | 2500--5000 | mm |

| 4 | Finished tube OD(mm) | 7~16 | mm |

| 5 | Finished tube WT(mm) | 0.7~2 | mm |

| 6 | Finished tube Length(m) | 20 | m |

| 7 | Stroke Frequency of Mill time/min | 80~180 | time/min |

| 8 | Stroke of Rolling mill bus(mm) | 392 | mm |

| 9 | Feeding Length(mm) | 1~6 | mm |

| 10 | rotation angle | 52° | |

| 11 | Roll Diameter(mm) | 151 | mm |

| 12 | Power(KW) | 45 | KW |

| 13 | Continous Rolling | Have |

LG10H Cold Pilger Mill Advantages:

Low maintenance cost

Easy operation(One person can operate two equipment)

Extremely high yield (improved by 60% to 150%)

Low break-down rate (servo structure)

Product with high precision

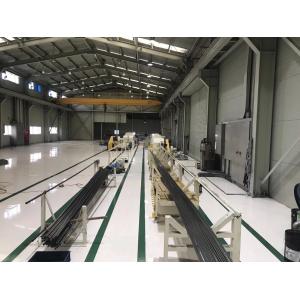

LG10H Cold Pilger Mill Equipment description

This mill is mainly composed of main power unit, main driving case,

saddles, stand base, billet chucks, carriage #1 and #2, mill bed #1

and #2, feeding and turning case #1 and #2, middle bed, mandrel

chucks, etc.

The power of the main power unit is mainly supplied through the

motor. The main driving unit includes a driving structure for

transmitting the power to the saddles. The saddles are moved in a

reciprocating way to drive the rolling of the product. The stand is

the working platform of saddles. The billet chuck is used for

rotating the billet. The carriage is used for driving forwards the

billet, and the mill bed is the working platform of the carriage.

The feeding and turning case is core part of equipment, and the

servo motor is used for controlling the rotating and feeding of

billet. The continuous feeding and rolling device, which includes

middle bed, carriage #2, mill bed #2, feeding and turning case #2,

and mandrel chuck #2, is an important part of continuous feeding

and rolling system. The mandrel chuck is mainly used for rotating

the mandrel.

Additional features

Technical Documents

All labels on machines and layout drawings, electrical diagram,

operated manual will be English and will be offered by manufacturer

after machine transported.

Company Introduction:

Zhangjiagang Hengli Machinery Co.,Ltd is specialized in developing and producing metallurgy machinery,food machinery and non-standard machinery etc. Various series of models can meet your demands in selection of LG series and LD series cold-rolling pipe mill, straightener and cold drawing machine and so on.

- Hengli gurantees that all the goods supplied are completely new, technically advanced, high quality and the design, materials and manufacturing process are defectless, they conform to the technical performance required by the customer and can run safely.

- Hengli gurantees that the gurantee period of the goods supplied is 12 months after the date of signing the certificate of goods acceptance.

- Hengli gurantees that the goods supplied meet the requirements for the quality and technical performace specified during the gurantee period, if it is due to the responsibility of Hengli that the goods supplied do not confirm to the requirements for the specified quality and technical performance, the buyer has the right to lodge the claim.

- Hengli gurantees that the technical documentation supplied is correct, complete and clear and conforms to the requirements for the design, inspection, installation, adjustment and maintance of the goods.