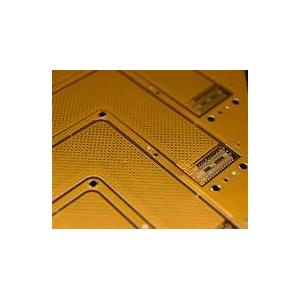

Polyimide Material Flexible Circuit Board PCB Model.No HSFPC10012 With 2 layers

Add to Cart

Polyimide Material Flexible Circuit Board PCB Model.No HSFPC10012 With 2 layers Finished Copper 1OZ Thickness 0.25mm

FAQ

Q: What files do you use in PCB fabrication?

A: Gerber or Eagle, BOM listing, PNP and Components Position

Q:Is it possible you could offer sample?

A: Yes, we can custom you sample to test before mass production

Q: When will I get the quotation after sent Gerber, BOM and test

procedure?

A: Within 6 hours for PCB quotation and around 24-48 hours for PCBA

quotation.

Q: How can I know the process of my PCB production?

A: 5-7days for PCB production and components purchasing, and 14

days for PCB assembly and Testing

Q: How can I make sure the quality of my PCB?

A: We ensure that each piece of PCB products work well before

shipping. We'll test all of them according to your test procedure.

Technical Specification | ||

Layers: | 1~10 (flex Pcb) and 2~8 (rigid flex) |

|

Min Panel Size: | 5mm x 8mm |

|

Max Panel Size: | 250 x 520mm |

|

Min Finished board thickness: | 0.05mm (1 sided inclusive copper) |

|

Max Finished board thickness: | 0.3mm (2 sided inclusive copper) |

|

Finished board thickness tolerance: | ±0.02~0.03mm |

|

Material: | Kapton, Polyimide, PET |

|

Base copper thickness (RA or ED): | 1/3 oz, 1/2 oz, 1oz, 2oz |

|

Base PI thickness: | 0.5mil, 0.7mil, 0.8mil, 1mil, 2mil |

|

Stiffner: | Polyimide, PET, FR4, SUS |

|

Min Finished hole diameter: | Φ 0.15mm |

|

Max Finished hole diameter: | Φ 6.30mm |

|

Finished hole diameter tolerance (PTH): | ±2 mil ( ±0.050mm) |

|

Finished hole diameter tolerance (NPTH): | ±1 mil ( ±0.025mm) |

|

Min width/spacing (1/3oz): | 0.05mm/0.06mm |

|

Min width/spacing (1/2oz): | 0.06mm/0.07mm |

|

Min width/spacing (1oz): | Single layer: 0.07mm/0.08mm |

|

Double layer: 0.08mm/0.09mm |

| |

Aspect Ratio | 6:01 | 8:01 |

Base Copper | 1/3Oz--2Oz | 3 Oz for Prototype |

Size Tolerance | Conductor Width:±10% | W ≤0.5mm |

Hole Size: ±0.05mm | H ≤1.5mm | |

Hole Registration: ±0.050mm |

| |

Outline Tolerance:±0.075mm | L ≤50mm | |

Surface Treatment | ENIG: 0.025um - 3um |

|

OSP: |

| |

Immersion Tin: 0.04-1.5um |

| |

Dielectric Strength | AC500V |

|

Solder Float | 288℃/10s | IPC Standard |

Peeling Strength | 1.0kgf/cm | IPC-TM-650 |

Flammability | 94V-O | UL |

PCB Assembly services:

SMT Assembly

Automatic Pick & Place

Component Placement as Small as 0201

Fine Pitch QEP - BGA

Automatic Optical Inspection

Through-hole Assembly

Wave Soldering

Hand Assembly and Soldering

Material Sourcing

IC pre-programming / Burning on-line

Function testing as requested

Aging test for LED and Power boards

Complete unit assembly (which including plastics, metal box, Coil,

cable assembly etc)

Packing design

Conformal coating

Both dip-coating and vertical spray coating is available.

Protecting non-conductive dielectric layer that is

applied onto the printed circuit board assembly to protect the

electronic assembly from damage due to

contamination, salt spray, moisture, fungus, dust and corrosion

caused by harsh or extreme environments.

When coated, it is clearly visible as a clear and shiny material.

Complete box build

Complete 'Box Build' solutions including materials management of

all components, electromechanical parts,

plastics, casings and print & packaging material

Testing Methods

AOI Testing

· Checks for solder paste

· Checks for components down to 0201"

· Checks for missing components, offset, incorrect parts, polarity

X-Ray Inspection

X-Ray provides high-resolution inspection of:

· BGAs

· Bare boards

In-Circuit Testing

In-Circuit Testing is commonly used in conjunction with AOI

minimizing functional defects caused by

component problems.

· Power-up Test

· Advanced Function Test

· Flash Device Programming

· Functional testing

Description

Your Best Choice for Flex PCB and Rigid-flex PCB Manufacturing

& Assembly

ADVANTAGES:

We product all kinds of Flex pcb and Rigid flex pcb which are

widely used in modern portable electronics and devices. Such as

Cell pone, key board, LCD module, Disk cable and etc.

1. With 15 years experience in circuit board, Printed Circuit Board

field to serve your needs

2. Competitive circuit board, Printed Circuit Board price with high

quality

3. Excellent service and prompt delivery

4. Our circuit board, Printed Circuit Board get ISO and UL

Certificates and meet ROHS REACH standard

1. Professional & experienced engineers

2. Competitive price

3. In time service

4. Product warranty

Detailed Specification of Pcb Assembly

1 | Type of Assembly | SMT and Thru-hole |

2 | Solder Type | Water Soluble Solder Paste,Leaded and Lead-Free |

3 | Components | Passives Down to 0201 Size |

BGA and VFBGA | ||

Leadless Chip Carries/CSP | ||

Double-Sided SMT Assembly | ||

Fine Pitch to 08 Mils | ||

BGA Repair and Reball | ||

Part Removal and Replacement-Same Day Service | ||

3 | Bare Board Size | Smallest:0.25x0.25 Inches |

Largest:20x20 Inches | ||

4 | File Formats | Bill of Materials |

Gerber Files | ||

Pick-N-Place File(XYRS) | ||

5 | Type of Service | Turn-Key,Partial Turn-Key or Consignment |

6 | Component Packaging | Cut Tape |

Tube | ||

Reels | ||

Loose Parts | ||

7 | Turn Time | 15 to 20 days |

8 | Testing | AOI inspection |

X-Ray inspection | ||

In-Circuit testing | ||

Functional test |