42CrMo4 Heat Treatment Alloy Steel Castings for Stacker Travelling Wheel

Add to Cart

42CrMo4 Heat Treatment Alloy Steel Castings for Stacker Travelling Wheel

1. Yield strength: σs (MPa):≥930(95);

2. Strength of extension σb (MPa):≥1080(110);

3. Percentage reduction of area ψ (%):≥45;

4. Elongation: δ5 (%):≥12;

5. Hardness:more than HRC40;

6. Conforming to EN 100831-1991;

7. Impact Value: more than AK78J.

8.The bolt holes are clean, smooth.

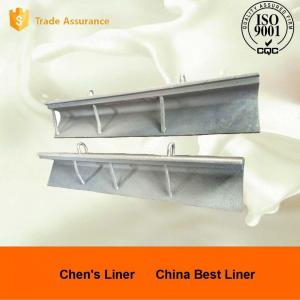

After shot blast After machining

packed in steel pallets

The general advantages in ball mills are as follows:

Output Increased | 5~20% |

Power Consumption Reduced | 5~20% |

Maintenance Decreased | Above 98% |

The liners are easily installed and existing mills need no modification. | |

The additional advantages in cement mills are as follows:

No leakage of slurry |

No repairs during service periods |

Better reliability and stability |

Production Improvement |

Noise reduction |

Technical Parameters

| Item | Cr-Mo Alloy Steel I | Cr-Mo Alloy Steel II | Cr-Mo Alloy Steel III |

| C | 0.30-0.50 | 0.65-0.90 | 0.40-0.90 |

| Si | 0.50-1.20 | ≤0.75 | 0.70-1.20 |

| Mn | 0.40-1.20 | 0.50-1.20 | 0.60-1.00 |

| Cr | 1.70-2.50 | 1.50-2.50 | 4.00-7.00 |

| S | ≤0.04 | ≤0.06 | ≤0.04 |

| P | ≤0.04 | ≤0.06 | ≤0.06 |

| Mo | ≤0.5 | ≤0.5 | ≤0.5 |

| Cu | 0.10-0.60 | ≤0.25 | 0.20-0.40 |

| Ni | ≤0.50 | ≤0.30 | ≤0.30 |

| Re | ≤0.02 | ≤0.02 | ≤0.02 |

| Equivalent Specifications | DL/T 681-1999 GB/T26651-2011 | AS 2074 L2B Mod | DL/T681-1999 |

| Material Type | Martensite Steel | Martensite or Pearlitic Cr Mo Steel | Martensite Steel |

| Hardness | HRc≥48 | HB470& HB321-370 | HRc≥50 |

| Impact Value | AK≥40J | - | AK≥10J |

| Item | High Cr white iron | High Cr Alloy Steel | High Manganese Steel | Ni-Hard cast iron |

| C | 2.40-3.20 | 1.1-2.2 | 0.90-1.30 | 2.40-3.60 |

| Si | 0.60-1.20 | 0.60-1.20 | ≤0.08 | ≤0.08 |

| Mn | 0.50-1.00 | 0.50-1.00 | 11.00-18.00 | ≤2.0 |

| Cr | 12.00-30.00 | 11.00-30.00 | 1.50-2.20 | 1.5-10.0 |

| S | ≤0.04 | ≤0.04 | ≤0.04 | ≤0.15 |

| P | ≤0.06 | ≤0.06 | ≤0.06 | ≤0.15 |

| Mo | 0.10-0.30 | 0.10-0.30 | ≤1.0 | ≤0.10 |

| Cu | 0.10-1.00 | 0.10-1.00 | - | - |

| Ni | 0-0.30 | 0-0.30 | - | 3.3-10.0 |

| Re | - | - | - | - |

| Equivalent Specifications | GB/T 8263-1999 AS 2027 Cr27 AS 2027 CrMo15/3 AS 2027 CrMo20/2/1 ASTM A532 Class III type A25%Cr ASTM A532 Class II type B15%Cr-Mo BS 4844 3E DIN1695 NFA32401 | BG/T 5680-1998 DL/T 681-1999 JIS G 5153-1999 ASTM A 128 DIN GX120Mn12 AFNOR:Z120Mn12 | GB/T 8263-1999 AS 2027/Ni-Cr1-550 AS 2027/Ni-Cr2-500 AS 2027/Ni-Cr4-500 AS 2027/Ni-Cr4-600 AS 2027/Ni-Cr4-630 ASTM A 532 1-A,B,C,D ASTM A 532 2-A,B,C,D,E ASTM A 532 3-A | |

| Material Type | Martensite matrix | Austenitic Mn Steel | - | |

| Hardness | HRc≥56 | HB≤300 | HRc≥56 | |

| Impact Value | AK≥4J | AK≥80J | - | |

Our foundry has complete melting, heat treatment and test equipments,such as mid frequency induction electrical furnaces,quenching and tempering furnaces,blast shot,spectrometer,Rockwell and Brinell

Hardness tester,impactor.UT tester and metallographic microscope. We achieved the certificate of quality management system ISO 9001:2000.

We have been exporting castings to oversea markets,such as Brazil,Australia and South Africa.